Hub-Tauch-Anlagen

OurSuper Wave-Series

Cleaning by immersion with a patented technology

Our ambition was to develop an economic solution with easy handling in a high quality for cleaning processes by immersion, e.g. degreasing, paint stripping, conservation, passivation or bonderising.

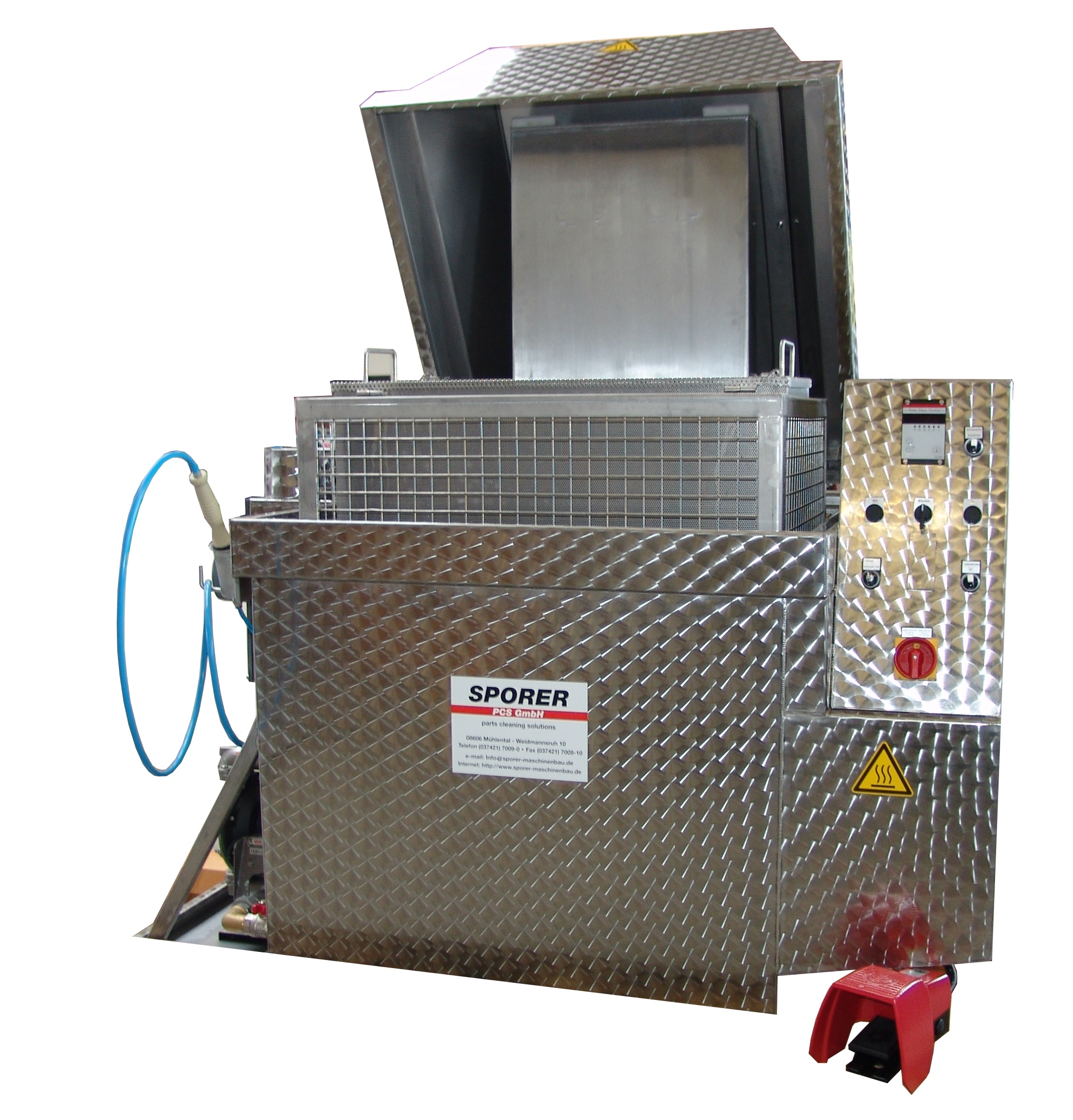

The result is our lift-dipping plant type SUPER WAVE, naturally in stainless steel like all our machines.

The SUPER WAVE is available in two standard versions:

SW-L for aqueous alkaline cleaning fluids with a pH from 7-12

SW-K for mineral solvents with a flash point above 62°C - on request

Ergänzendes

Product

This innovative machine works with a linear lift-dipping process. The internationally patented construction of the new clack valve system produces an exceptional cleaning result.

The combination of two or more machines in a line offers the possibility to integrate different cleaning processes on an economic price level.

Normal lift-dipping machines have the problem, that oil from the cleaned parts floats on the surface of the bath. By lifting the lifting table, the cleaned parts pass through the oil and get dirty again. In the Super Wave, we resolved this problem. We developed the surface rinsing with a separating system. In this way, oil is separated from the water and the parts are not soiled again.

Application

This machine is conceived for aqueous, alkaline cleaning agents with a pH value from 7-12.

We recommend the Super Wave for oily and dusty parts, e.g. motor blocks, tubes, plates etc. Parts with holes or blind holes can also be washed in this machine, but the diameter of the holes remains an important factor.

Ou lift-dipping plants can also be equipped with specific equipment for paint-stripping and bonderising.

Mode of operation

Cleaning by immersion is carried out with an oscillating lifting and dipping of the pneumatic lifting unit into the bath. This effectuates a thorough cleaning of the parts, reinforced by the patented clack valve system that optimises the swirling of the medium.

By opening the cover, the lifting unit lifts automatically into the position for loading and unloading (upper edge of the machine). The dirty parts can be loaded. After pressing the button "Close" and activating the switch "Washing", the lifting unit dips inside the bath, the cover is closed automatically. As long as the switch "Washing" is activated, the lifting unit effectuates continuous lift and dipping movements inside the bath.

The loading platform disposes of cavities and clacks. Those clacks can close the cavities (clack valve system). When moving the loading platform down, the clacks will close the cavities and the medium bathes the dirty parts. When moving the loading platform up the clacks will open and medium flows through the parts. This technology achieves a very effective cleaning result.

Technical Data

| SW-L 8/6 | SW-L 16/6 | |

|---|---|---|

| Nominal input voltage | 400 V / 50 Hz / 16 A | 400 V / 50 Hz / 32 A |

| Usable width | 800 mm | 1600 mm |

| Usable depth | 600 mm | 600 mm |

| Usable height | 300 mm | 300 mm |

| External dimensions WxDxH | 1300 x 1035 x 1250 mm | 2180 x 1035 x 1420 mm |

| Max. loading capacity | 100 kg | 100 kg |

| Max. tank volume | 250 - 300 l | 500 - 650 l |

| Height of strokes | bis 60 mm | bis 60 mm |

| Strokes (max. loading capacity) | 25 strokes | 25 strokes |

| Strokes (unloaded) | 50 strokes | 50 strokes |

| Necessary compressed air connection | 8 bar 3/8" - 1/2" | 8 bar 3/8" - 1/2" |

| Heating | 7,5 kW | 12 kW |

| Operating temperature - standard | 62°C | 62°C |

| Operating temperature - optional | 75°C | 75°C |

| On-time | 70 % | 70 % |

Standard equipment

- Conceived for alkaline aqueous cleaning fluids with a pH-value from 7-12

- Solid washing tank made from stainless steel

- The washing tank is completely insulated

- Slewing cover in stainless steel - opening and closing of the cover by a pneumatic cylinder

- Continuous oscillating movements - The swirling of the medium is intensified by the patented clack valve system

- Protection against dry-running - Safety shut down of the heater when the medium level is too low

- Digital temperature control

- Tubular electric heater made from stainless steel

- Switchboard conform to VDE-instructions

- Solid and compact construction with a clear arrangement of the operating elements

- Machine conform to CE

Optional equipment

The following standard equipment is available:

- Drain cock

- Collecting pan

- Transport trolley

- Automatic level control

- Oil separator

- Surface oil removal

- Additional filtration

- small parts baskets in stainless steel

- Cleaning agent

Further options on demand.